The FH-200 Alkaline Copper Brightener is a specially developed additive designed for the bright copper plating process. Manufactured by Shenzhen Xinfuhua Surface Technology Co., Ltd., a professional enterprise established in 2005 and specialized in Electroplating Additives, FH-200 is a high-performance solution engineered to produce smooth, bright, and uniform copper deposits.

With years of research and development experience in the electroplating industry, our company has integrated advanced international technology and strict quality management standards to ensure that FH-200 delivers consistent plating performance, superior brightness, excellent leveling ability, and stable operation in industrial applications.

Copper plating plays a vital role in the electroplating industry, often serving as a key intermediate layer before nickel, chromium, or precious metal coatings. Traditional copper plating processes sometimes face issues such as poor brightness, uneven plating thickness, or surface roughness.

The FH-200 Alkaline copper brightener is specifically formulated to overcome these challenges. It provides:

Excellent leveling ability, ensuring that the plated surface is smooth and defect-free.

High brightness and gloss, delivering decorative and functional plating finishes.

Stable bath performance, reducing the frequency of adjustments and prolonging bath life.

FH-200 is suitable for both rack plating and barrel plating systems, making it an ideal solution for industries requiring consistent copper deposits across complex shapes and high-volume parts.

High brightness – Produces mirror-like copper deposits with excellent reflectivity.

Superior leveling effect – Smoothens substrate defects and ensures a uniform surface finish.

Stable formulation – Maintains consistent plating quality even under high current density.

Wide current density range – Suitable for both low and high current density operations.

Excellent adhesion – Ensures strong bonding between the copper layer and the substrate.

Long bath life – Minimizes additive consumption and reduces production costs.

Compatibility – Suitable for various plating lines including electronics, hardware, and decorative finishing.

Improves Surface Brightness: Provides a mirror-like, decorative copper finish.

Enhances Adhesion: Ensures that subsequent nickel or chromium layers adhere effectively.

Defect Coverage: Reduces roughness and covers minor surface imperfections.

Uniform Plating: Ensures consistent thickness across different shapes and sizes of components.

Bath Stabilization: Maintains plating bath stability, reducing the need for frequent corrections.

Process Efficiency: Increases plating speed while keeping energy consumption low.

High Quality Results: Achieves outstanding brightness and leveling, comparable to international leading brands.

Cost Savings: Long bath life and low additive consumption help reduce operating costs.

Operational Flexibility: Performs well in a wide range of operating conditions and plating systems.

Environmental Considerations: Designed with modern safety and environmental standards in mind.

Technical Support: Backed by Shenzhen Xinfuhua’s expertise and professional technical service team.

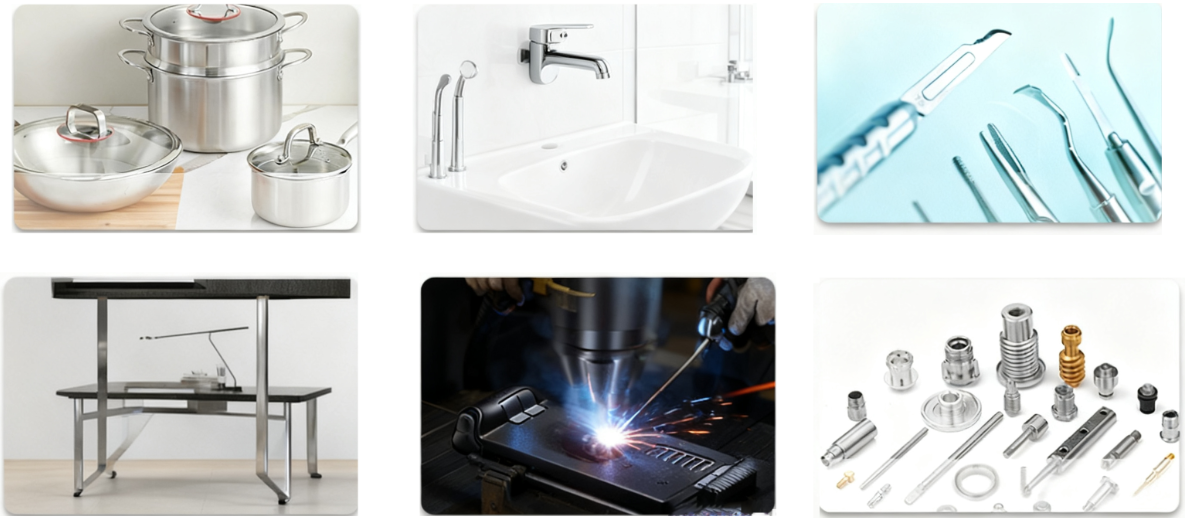

The FH-200 Alkaline Copper Brightener is widely applied in industries requiring decorative and functional copper plating, including:

Electronics Industry: For plating connectors, printed circuit boards (PCB), and precision parts.

Automotive Industry: Used in decorative plating of trims, handles, and functional automotive parts.

Hardware Manufacturing: For tools, fasteners, and metal accessories requiring high surface finish.

Jewelry and Decorative Items: Provides bright copper coating for ornaments and luxury goods.

Aerospace & Precision Engineering: Ensures reliable copper deposits for high-precision components.

General Industrial Use: Applied in rework, intermediate coatings, and base layer preparation.

Q1: What type of copper plating is FH-200 designed for?

A1: FH-200 is developed for alkaline bright copper plating processes, offering excellent brightness and leveling effects.

Q2: Can FH-200 be used in both rack and barrel plating systems?

A2: Yes, FH-200 is suitable for both rack plating and barrel plating, ensuring consistent performance in different applications.

Q3: How does FH-200 improve plating adhesion?

A3: The additive enhances bonding strength between the copper layer and the substrate, ensuring stable adhesion for subsequent nickel or chromium plating.

Q4: What is the current density range for FH-200?

A4: FH-200 performs well across a wide current density range, making it adaptable to different production conditions.

Q5: Does FH-200 require frequent bath adjustments?

A5: No, FH-200 provides stable bath performance, reducing the need for constant monitoring and adjustments.

Q6: Is FH-200 Environmentally Friendly?

A6: Yes, FH-200 is designed with reduced environmental impact and complies with modern Plating Safety standards.

Q7: What industries benefit the most from FH-200?

A7: Electronics, automotive, hardware, aerospace, and decorative industries commonly use FH-200 for high-quality bright copper plating.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.