Traditional chromium plating, while widely used, poses challenges due to its environmental hazards and regulatory restrictions. The FH-80 White Tin Cobalt additive is specifically formulated as a chromium substitute, creating a coating with similar brightness, hardness, and Corrosion Resistance to conventional chromium plating but without the environmental risks.

Through advanced R&D and ISO9001:2004 quality management systems, FH-80 delivers a smooth, white metallic finish with excellent wear resistance, adhesion, and decorative appearance. This product is compatible with a wide range of plating equipment, suitable for rack plating, barrel plating, and continuous plating production lines.

Chromium substitute – Provides a white metallic finish comparable to chromium plating.

Eco-friendly formulation – Eliminates toxic hexavalent chromium, reducing environmental impact.

Excellent corrosion resistance – Protects base metals from oxidation and degradation.

High hardness & wear resistance – Extends the service life of plated components.

Bright white appearance – Produces a clean, decorative finish suitable for consumer products.

Strong adhesion – Ensures stable coating without peeling or flaking.

Stable bath performance – Maintains consistent plating quality with minimal maintenance.

Ingredients | Scope | Unit |

FH80 Bottle Opener | 1000 | ml/L |

Temperature | 40-45 | °C |

pH value | 8.5-9.5 | |

Anode | Graphite plate | |

Anode current density | 0.1-0.5 | A/dm2 |

Surface Protection: Offers long-lasting corrosion resistance comparable to chromium plating.

Decorative Coating: Provides a bright white metallic finish for consumer and industrial products.

Chromium Replacement: Reduces reliance on environmentally hazardous chromium-based plating.

Functional Layer: Adds hardness and wear resistance to mechanical and electronic parts.

Wide Compatibility: Can be applied on hardware, automotive, electronic, and precision components.

Environmental Compliance – Meets global environmental regulations by replacing hexavalent chromium.

Cost Efficiency – Reduces waste treatment costs associated with chromium plating.

Superior Performance – Matches or exceeds the protective and decorative qualities of traditional chromium.

Process Flexibility – Suitable for rack, barrel, and automated plating systems.

Stable Production – Easy bath control and extended bath life ensure continuous high-quality results.

Customer-Oriented – Developed with advanced electroplating additive technologies for international markets.

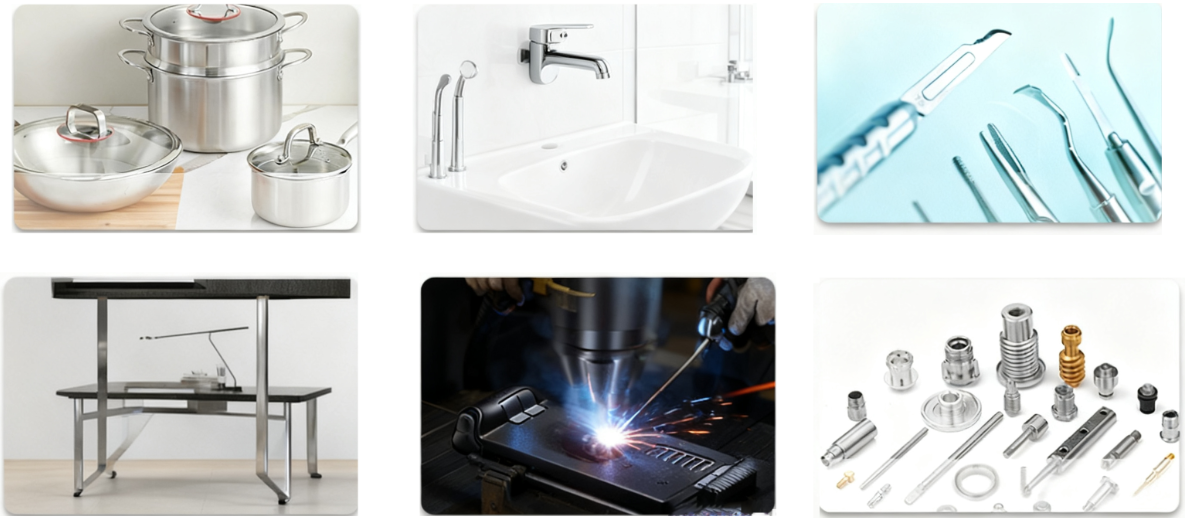

The FH-80 White Tin Cobalt (Chromium Substitute) is widely used in:

Automotive Industry: Decorative and protective coatings for trim parts, handles, and precision components.

Electronics & Electrical: Surface protection for connectors, housings, and functional parts.

Hardware & Tools: Provides durable coatings with bright white finishes.

Consumer Products: Suitable for household appliances, decorative hardware, and wear-resistant items.

Aerospace & Aviation: Applied in lightweight, high-strength, corrosion-resistant coatings.

Medical Devices: Used in applications requiring non-toxic, durable, and safe coatings.

Q1: What makes FH-80 a chromium substitute?

A1: FH-80 uses a tin-cobalt alloy plating system that replicates the brightness, durability, and corrosion resistance of chromium without environmental hazards.

Q2: Is FH-80 Environmentally Friendly?

A2: Yes, FH-80 eliminates toxic hexavalent chromium, making it a safer and eco-friendly plating solution.

Q3: What industries benefit most from FH-80?

A3: Automotive, electronics, hardware, aerospace, and consumer products industries all benefit from FH-80’s decorative and functional plating capabilities.

Q4: How does FH-80 compare to traditional chromium plating?

A4: FH-80 provides a similar appearance and durability, while offering better environmental compliance and reduced operational risks.

Q5: Can FH-80 be used in automated plating lines?

A5: Yes, FH-80 is compatible with both manual and automated plating systems, ensuring production efficiency.

Q6: Does FH-80 require special maintenance?

A6: No, FH-80 is formulated for stable bath performance and requires only standard monitoring procedures.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.