nickel plating is a critical process in the electronics, hardware, automotive, and decorative industries due to its superior Corrosion Resistance, hardness, and aesthetic appearance. The FH-806 bright nickel additive is optimized for high-speed rack plating, offering outstanding performance even under heavy workloads.

Supported by ISO9001:2004 quality management systems and years of electroplating R&D expertise, FH-806 guarantees stable bath chemistry, reduced defects, and consistent plating quality. It is easy to maintain, cost-effective, and suitable for high-volume industrial production lines.

High-speed plating performance – Achieves rapid nickel deposition for improved productivity.

Superior brightness – Produces a mirror-like, smooth, and highly reflective nickel surface.

Excellent leveling ability – Ensures uniform thickness distribution, even on complex geometries.

Strong adhesion – Provides reliable bonding between the nickel layer and substrate.

Wide operating range – Stable across varied plating conditions with minimal adjustment.

Durable bath chemistry – Long bath life reduces maintenance frequency and cost.

Environmentally optimized – Lower environmental impact compared to traditional nickel Solutions.

Bright nickel coating – Provides an attractive, high-gloss decorative finish.

Corrosion protection – Enhances durability and resistance to oxidation.

Functional layer – Serves as a protective underlayer for subsequent coatings (e.g., chromium plating).

Wear resistance – Increases hardness and extends component lifespan.

Uniform deposition – Maintains coating consistency across large rack plating setups.

Ingredients | Scope | Unit |

Nickel sulfate | 180-250 | g/L |

Nickel chloride | 40-50 | g/L |

Borax | 30-40 | g/L |

FH806 Brightener | 0.2-0.4 | ml/L |

FH806 Softener | 6-10 | ml/L |

FH806 Moisturizer | 0.4-0.6 | ml/L |

Temperature | 50-60 | °C |

pH value | 4.0-4.5 | |

Cathode current density | 2-8 | A/dm2 |

Anodic current density | 1-4 | A/dm2 |

Stir | Air or mechanical stirring |

High Efficiency – Faster deposition rate increases production output.

Outstanding Appearance – Produces brilliant, smooth, and defect-free surfaces.

Stable Performance – Maintains consistent quality even under high-speed operations.

Cost Savings – Long bath life and reduced chemical consumption lower production costs.

Wide Application – Suitable for decorative and functional coatings across multiple industries.

Reliable Quality Control – Manufactured under strict ISO-certified systems to ensure repeatable results.

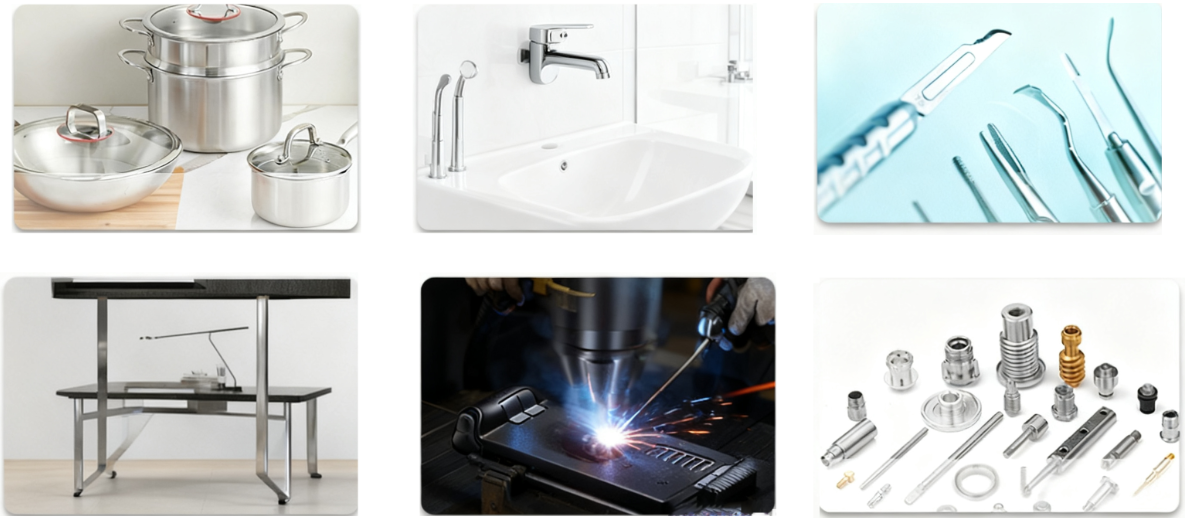

The FH-806 High-Speed Bright Nickel Additive is widely used in:

Electronics Industry: Nickel plating for connectors, terminals, and precision components.

Automotive Industry: Decorative bright nickel coatings for trims, handles, and functional parts.

Hardware Manufacturing: Surface finishing of fasteners, tools, and decorative hardware.

Appliance Industry: Enhances appearance and protection of home appliance components.

General Industrial Use: Suitable for any rack plating process requiring bright nickel finishes.

Q1: What makes FH-806 suitable for high-speed rack plating?

A1: FH-806 is formulated to maintain stability at high current densities, ensuring rapid deposition without compromising surface quality.

Q2: Does FH-806 produce bright finishes consistently?

A2: Yes, FH-806 produces mirror-like bright finishes with excellent leveling, even under varying plating conditions.

Q3: Can FH-806 be used for both decorative and functional applications?

A3: Absolutely. It provides both aesthetic appeal and corrosion resistance, making it suitable for diverse applications.

Q4: How long is the bath life of FH-806?

A4: FH-806 offers extended bath life with minimal maintenance, reducing operational downtime.

Q5: Is FH-806 environmentally safe?

A5: Yes, FH-806 is developed with environmentally optimized components, reducing ecological impact compared to conventional bright nickel additives.

Q6: What industries benefit most from FH-806?

A6: Electronics, automotive, hardware, and appliance industries rely heavily on FH-806 for reliable, bright, and durable nickel coatings.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.