In Electroplating Processes, surface preparation is critical to achieving durable and high-performance coatings. Copper and copper alloys often require effective pretreatment to remove oxidation, scratches, and other surface defects.

The FH-66 Copper Alloy Chemical Polishing Agent provides a uniform, mirror-like surface finish by chemically dissolving microscopic roughness and contaminants. Unlike mechanical polishing, FH-66 achieves polishing at a microscopic level, offering higher efficiency, better consistency, and reduced labor intensity.

Developed with advanced electroplating additive technology, FH-66 integrates international polishing formulations and complies with ISO9001:2004 quality standards. It ensures stable bath performance, easy operation, and excellent compatibility with subsequent electroplating processes.

High polishing efficiency – Rapidly removes oxides and contaminants from copper alloy surfaces.

Mirror-like finish – Produces a smooth, reflective, and uniform surface.

Improved adhesion – Provides a clean and active surface for stronger electroplated coatings.

Stable bath chemistry – Long-lasting performance with minimal decomposition.

Reduced defects – Eliminates pitting, streaks, and uneven surfaces before plating.

Easy operation – Compatible with standard pretreatment lines, requiring minimal adjustments.

Environmentally optimized – Formulated to reduce harmful emissions compared to traditional polishing Solutions.

Oxide removal – Efficiently removes copper oxide and tarnish layers.

Surface leveling – Smooths out micro-scratches and uneven textures.

Brightness enhancement – Provides a shiny surface, improving decorative and functional plating outcomes.

Electroplating pretreatment – Ensures superior adhesion and quality of subsequent coatings.

Corrosion Prevention – Prepares the substrate to resist defects during plating.

High-Quality Surface Preparation – Ensures consistent polishing results, critical for premium plating.

Enhanced Productivity – Faster polishing process reduces production cycle times.

Cost Efficiency – Prolonged bath life lowers chemical consumption and operating costs.

Strong Compatibility – Suitable for different copper alloys and electroplating lines.

Improved Plating Performance – Minimizes plating defects, blistering, and peeling.

Safer and Cleaner Process – Lower toxicity compared to conventional chemical polishing agents.

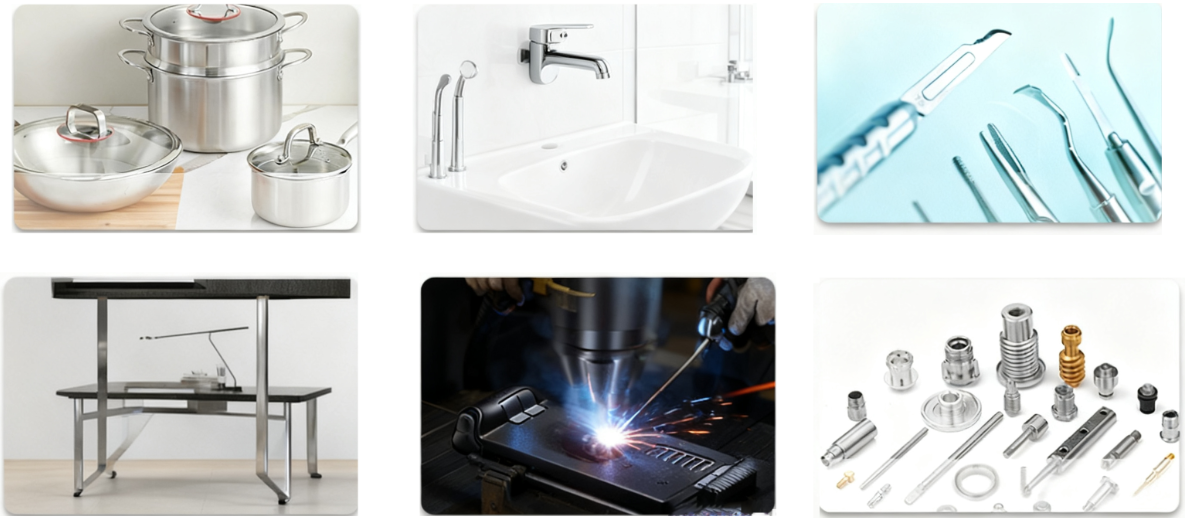

The FH-66 Copper Alloy Chemical Polishing Agent is widely applied in:

Electronics Industry: Pre-polishing of connectors, lead frames, and PCB copper layers.

Hardware Manufacturing: Surface treatment of copper alloy fasteners, tools, and decorative hardware.

Jewelry & Decorative Plating: Enhances brightness and finish of copper-based ornaments.

Automotive Components: Pretreatment of copper and brass parts for durable coatings.

Precision Engineering: Applied in medical devices, aerospace components, and fine instruments requiring flawless plating quality.

General Industrial Plating: For any copper alloy substrate needing superior pretreatment.

Q1: What is FH-66 mainly used for?

A1: FH-66 is used for chemical polishing of copper and copper alloy substrates before electroplating, ensuring smooth and bright surfaces.

Q2: Does FH-66 damage the base material?

A2: No, FH-66 is carefully formulated to polish copper alloys without excessive erosion or damage to the substrate.

Q3: How does FH-66 improve Electroplating Quality?

A3: By removing oxides and surface defects, FH-66 creates a clean and active surface that enhances plating adhesion and brightness.

Q4: Is FH-66 suitable for automated production lines?

A4: Yes, FH-66 is compatible with both manual and automated chemical polishing lines.

Q5: What safety precautions are needed?

A5: Standard chemical handling measures should be followed, including protective gloves, goggles, and adequate ventilation.

Q6: How long does the polishing bath last?

A6: FH-66 offers excellent bath stability and extended service life, reducing the need for frequent replacement.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.