In electroplating, surface cleanliness is the foundation of Coating Quality. Any residual wax, grease, or oil can lead to poor adhesion, uneven plating, or coating defects. The FH-7 Universal Wax Remover is developed as a specialized pretreatment agent to eliminate such contaminants before plating operations.

By combining advanced degreasing and wax-removing additives, FH-7 ensures surfaces are thoroughly cleaned without corroding or damaging the base material. It can be used in various cleaning processes including soaking, ultrasonic cleaning, and circulation systems, making it a versatile solution for different industrial environments.

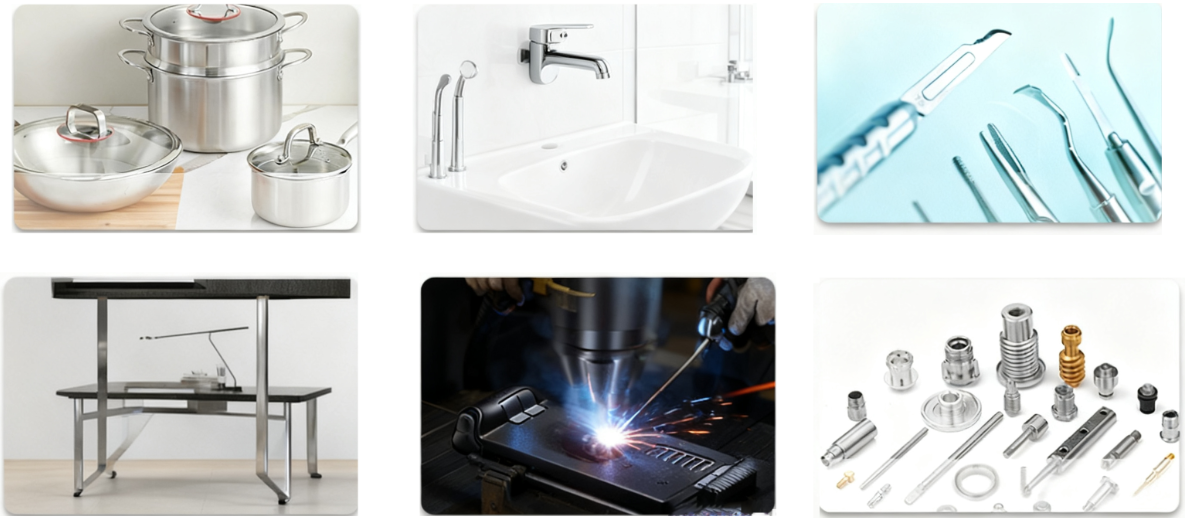

With its high removal efficiency, stable performance, and environmentally conscious formulation, FH-7 is widely applied in electronics, automotive, aerospace, hardware, and precision manufacturing industries.

Universal application – Suitable for removing wax, grease, and oil from multiple metal substrates.

Efficient cleaning – Provides deep cleaning for excellent electroplating adhesion.

Non-corrosive formulation – Protects base materials from damage during cleaning.

Stable performance – Maintains effectiveness over long bath life and repeated usage.

Versatile usage – Applicable in immersion, ultrasonic, or circulation cleaning systems.

Eco-friendly design – Lower environmental impact compared to conventional harsh cleaners.

Wax removal – Eliminates wax residues from components before plating.

Degreasing – Removes oil and grease layers to improve plating adhesion.

Surface activation – Prepares substrates for uniform and defect-free coating.

Adhesion improvement – Ensures electroplated coatings bond strongly with base material.

Defect prevention – Reduces blistering, peeling, or uneven deposits caused by contaminants.

Ingredients | Scope | Unit |

FH7 Universal De-waxing Water | 70 | ml/L |

Temperature | 75 | °C |

Time | 1-3 | Minute |

Stir | Ultrasonic vibration or hot dip |

Superior Cleaning Efficiency – Quickly dissolves and removes stubborn wax and grease residues.

Enhanced Plating Quality – Provides a clean and active surface, ensuring uniform and reliable coatings.

Operational Flexibility – Can be used in different pretreatment setups (manual, automated, ultrasonic).

Cost-Effective – Long bath life reduces frequency of replacement, lowering production costs.

Safe and Reliable – Formulated with reduced corrosive agents, ensuring operator and equipment safety.

Wide Industry Compatibility – Ideal for electronics, automotive, aerospace, and Hardware Plating lines.

The FH-7 Universal Wax Remover is widely used in:

Electronics Industry: For cleaning PCB boards, connectors, and micro-components before plating.

Automotive Industry: Removing wax and grease from car parts requiring electroplating.

Aerospace Industry: Ensuring high-precision metal parts are contaminant-free for durable coatings.

Hardware & Tools: Cleaning fasteners, tools, and decorative hardware for smooth plating finishes.

Jewelry & Decorative Plating: Prepares surfaces for bright, uniform, and defect-free coatings.

General Industrial Plating: Suitable for all electroplating lines requiring effective pretreatment.

Q1: What is FH-7 Universal Wax Remover used for?

A1: FH-7 is designed for removing wax, grease, and oil residues from metal surfaces before electroplating, ensuring better coating adhesion.

Q2: Is FH-7 safe for all base metals?

A2: Yes, FH-7 has a non-corrosive formulation that protects common substrates such as steel, copper, nickel, and aluminum.

Q3: Can FH-7 be used in automated cleaning systems?

A3: Yes, FH-7 is compatible with immersion tanks, ultrasonic cleaners, and automated circulation systems.

Q4: How does FH-7 improve plating quality?

A4: By removing contaminants, FH-7 ensures a clean and active surface, preventing defects like peeling, blistering, or poor adhesion.

Q5: Does FH-7 require frequent bath replacement?

A5: No, FH-7 has a long bath life and maintains stability, reducing operational costs.

Q6: Is FH-7 Environmentally Friendly?

A6: FH-7 is formulated with reduced hazardous substances, making it safer for operators and more eco-friendly compared to traditional cleaners.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.