Surface pretreatment is a critical step in the Electroplating Process. Any residual oil, grease, or contaminants on the workpiece surface can significantly affect plating adhesion, uniformity, and overall performance. The FH-50 Universal Hot-dip Degreasing Powder is specifically formulated to solve this issue by delivering deep and thorough cleaning through immersion processes.

By incorporating advanced additive technology and adhering to ISO9001:2004 quality management standards, FH-50 guarantees high-efficiency degreasing without corroding or damaging the base material. Its universal formulation makes it suitable for steel, copper, aluminum, zinc alloys, and other common plating substrates.

FH-50 can be applied in manual, semi-automatic, and fully automatic pretreatment lines, ensuring stable and consistent performance in large-scale industrial production.

Strong degreasing power – Effectively removes oils, greases, and contaminants from various metal surfaces.

Universal compatibility – Suitable for a wide range of ferrous and non-ferrous substrates.

Excellent cleaning stability – Maintains high performance even under long-term operation.

Hot-dip formulation – Enhanced cleaning efficiency at elevated temperatures.

Substrate protection – Non-corrosive and safe for delicate parts.

Easy handling – Powder form simplifies storage, transportation, and bath preparation.

Environmentally optimized – Reduced environmental impact compared to traditional degreasing chemicals.

Surface Cleaning – Removes stubborn oil films, grease, dirt, and processing residues.

Adhesion Improvement – Ensures better bonding strength of electroplated layers.

Corrosion Prevention – Prepares a stable and contamination-free surface for plating.

Process Optimization – Reduces plating defects caused by poor surface preparation.

Bath Stability – Long-lasting cleaning efficiency with low consumption rates.

High Efficiency: Fast and thorough degreasing ensures improved plating productivity.

Cost-effective: Extended bath life and low dosage requirements reduce overall costs.

Safe & Reliable: Gentle on substrates, preventing etching or pitting.

Flexible Application: Suitable for immersion tanks in both manual and automatic pretreatment lines.

ISO-Certified Quality: Developed under strict quality control to ensure stable performance.

Global Standard Compliance: Environmentally optimized to meet international environmental and safety requirements.

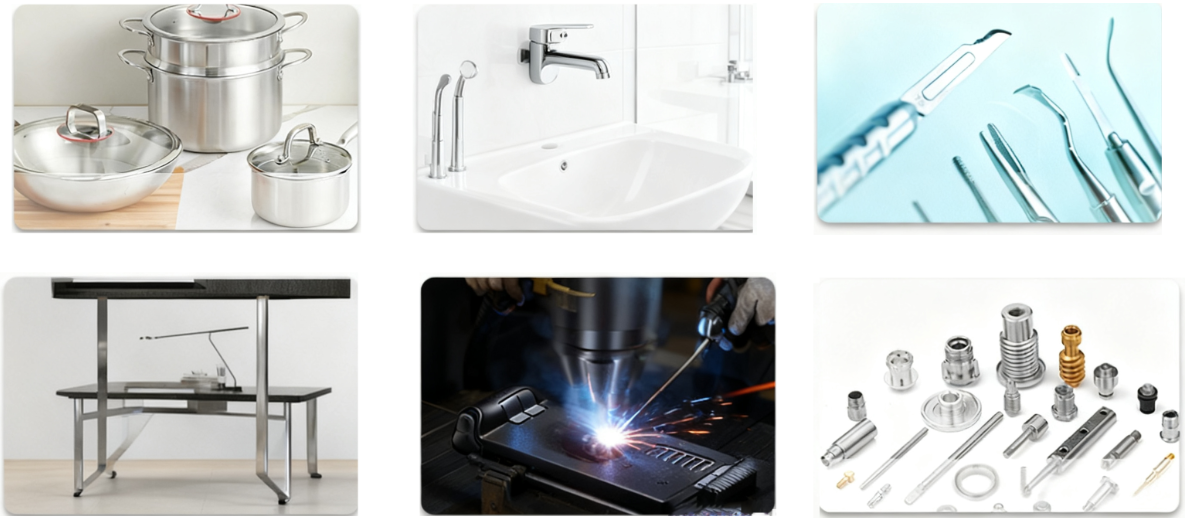

The FH-50 Universal Hot-dip Degreasing Powder is widely applied in:

Electronics Industry: Pretreatment of connectors, PCB parts, and micro-components.

Automotive Industry: Cleaning metal components before decorative and functional plating.

Hardware Manufacturing: Degreasing screws, fasteners, and precision tools.

Aerospace & Aviation: Preparing high-precision aircraft parts for electroplating.

Medical Devices: Cleaning stainless steel surgical instruments and medical equipment.

General Metal Finishing: Pre-cleaning of copper, aluminum, zinc alloy, and steel parts.

Q1: What metals can FH-50 be used on?

A1: FH-50 is suitable for ferrous metals (such as steel and iron) as well as non-ferrous substrates like copper, aluminum, and zinc alloys.

Q2: How should FH-50 be applied?

A2: FH-50 is designed for hot-dip immersion degreasing tanks, with optimal performance at elevated temperatures.

Q3: Does FH-50 damage sensitive base materials?

A3: No, FH-50 is formulated to protect substrates and does not cause corrosion or pitting when used as directed.

Q4: Can FH-50 be used in automated production lines?

A4: Yes, FH-50 is compatible with both manual and automated pretreatment systems, making it ideal for high-volume production.

Q5: How often does the degreasing bath need replacement?

A5: FH-50 provides long bath life and stable performance, reducing the frequency of replacement and lowering operating costs.

Q6: Is FH-50 environmentally safe?

A6: Yes, FH-50 is designed with Eco-Friendly Additives and complies with international safety and environmental standards.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.