Electroplating pre-treatment plays a crucial role in ensuring the success of plating processes. Surface impurities such as oils, lubricants, and dirt can lead to poor adhesion, uneven coating, and plating defects. The FH-60 General-purpose Electrolysis Oil Powder is a versatile cleaning and degreasing solution formulated with advanced electrolysis technology.

FH-60 combines powerful cleaning agents and electrolytic additives, allowing for both chemical and electrochemical removal of organic and inorganic contaminants. It provides a stable and long-lasting degreasing effect, ensuring that metal surfaces are thoroughly cleaned and activated before the plating process.

Developed under ISO9001:2004 certified production standards, FH-60 ensures consistent quality, safe operation, and reliable results for electroplating factories worldwide.

Excellent degreasing performance – Effectively removes oil, grease, and fingerprints from metal surfaces.

Wide metal compatibility – Suitable for steel, copper, aluminum, zinc, and alloy materials.

Electrochemical cleaning action – Combines chemical cleaning with electrolytic degreasing for superior results.

Strong emulsification & penetration – Quickly breaks down and disperses stubborn oil contaminants.

Stable alkaline formula – Provides consistent cleaning even under high-temperature and long-term operation.

Easy to use & maintain – Simple bath preparation and stable concentration control.

Environmentally optimized – Reduced harmful emissions and safer handling compared to traditional cleaners.

Oil and Grease Removal – Removes industrial oils, machining lubricants, and fingerprints.

Surface Activation – Prepares and activates metal surfaces for better adhesion in subsequent plating.

Rust Prevention – Reduces surface oxidation during cleaning, keeping substrates stable.

Defect Reduction – Prevents plating problems such as peeling, pitting, and uneven coatings.

Improved Efficiency – Ensures clean substrates, reducing rework and improving production yield.

High Cleaning Efficiency – Ensures quick and complete removal of surface contaminants.

Reliable Quality – Developed with advanced R&D and strict ISO-certified standards.

Cost-effective – Long bath life reduces chemical consumption and maintenance costs.

Flexible Application – Works in both rack plating and barrel plating production lines.

Safer Operation – Lower toxicity formulation reduces operator risk and environmental impact.

Global Recognition – Trusted by electroplating factories across hardware, automotive, and electronics industries.

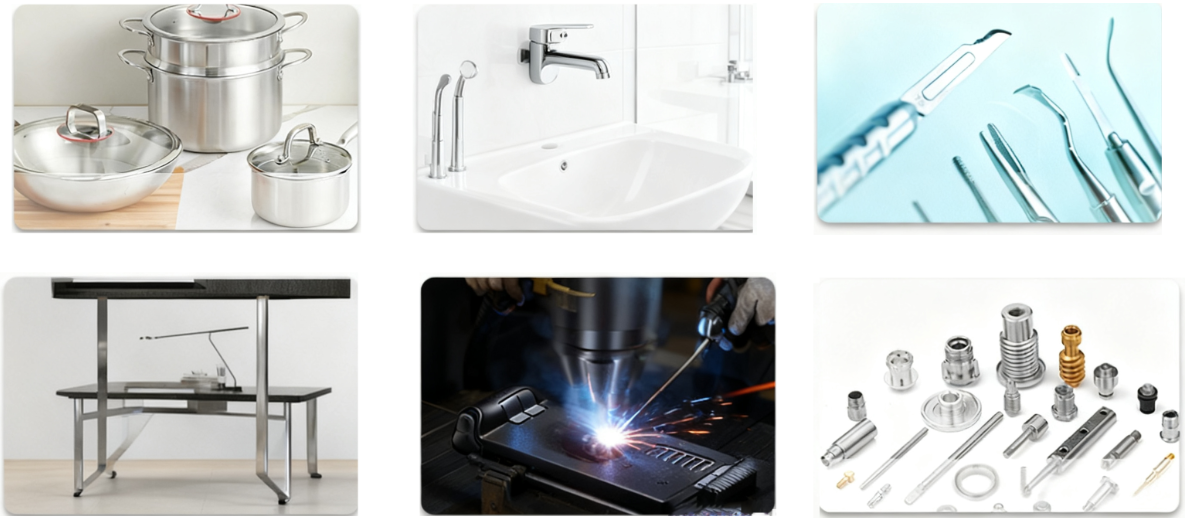

The FH-60 General-purpose Electrolysis Oil Powder is widely used in:

Electronics Manufacturing: Cleaning and activating connectors, circuit boards, and precision parts.

Hardware Industry: Pre-treatment for fasteners, tools, and decorative Hardware Plating.

Automotive Industry: Degreasing of automotive components before chrome, nickel, or zinc plating.

Aerospace and Aviation: Cleaning precision parts requiring high plating reliability.

General Industrial Plating: Suitable for all electroplating workshops that require effective degreasing.

Q1: What metals can FH-60 be used on?

A1: FH-60 is suitable for steel, copper, aluminum, zinc, and alloys.

Q2: Does FH-60 work in both manual and automated production lines?

A2: Yes, FH-60 can be applied in both manual cleaning tanks and automatic electroplating production lines.

Q3: Is FH-60 safe for operators?

A3: FH-60 is formulated with reduced toxicity. Standard protective equipment (gloves, goggles) should be used for safe handling.

Q4: How does FH-60 differ from traditional oil-removing powders?

A4: FH-60 combines chemical cleaning with electrolysis for stronger degreasing and longer bath stability.

Q5: Can FH-60 prevent plating defects?

A5: Yes, by ensuring thorough cleaning and surface activation, FH-60 minimizes plating problems such as peeling and pitting.

Q6: What bath conditions are recommended?

A6: Optimal performance is achieved under stable alkaline conditions with proper temperature control, following technical guidelines.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.