Black nickel plating is widely used in functional and decorative Electroplating Processes, offering both a distinctive aesthetic appearance and enhanced performance characteristics. The FH-230 black nickel Additive has been carefully formulated to meet the demands of modern plating industries by providing a stable, easy-to-control plating bath capable of delivering consistent and reliable results.

This product integrates advanced electroplating additive technology with strict ISO9001:2004 quality management standards, ensuring high-quality black nickel finishes that meet international requirements. FH-230 is suitable for both rack plating and barrel plating, and can be used on a wide variety of substrates including copper, brass, zinc alloys, and nickel underlayers.

Deep black finish – Produces a uniform, non-reflective black nickel coating.

Stable bath performance – Maintains consistent plating quality over long production cycles.

Excellent adhesion – Strong bonding to base metals and underlayers prevents peeling.

High wear resistance – Enhances surface hardness and durability.

Corrosion protection – Provides additional protection against oxidation and environmental damage.

Good coverage & throwing power – Ensures uniform plating even on complex shapes and edges.

Versatile application – Suitable for both decorative and functional electroplating processes.

Decorative Coating – Adds a stylish and premium black finish for high-end hardware, accessories, and consumer products.

Protective Layer – Improves Corrosion Resistance and extends the lifespan of plated components.

Functional Performance – Reduces reflectivity, making it suitable for optical and aerospace applications.

Wear Resistance – Enhances the surface hardness and durability of mechanical and electrical parts.

Undercoat Compatibility – Works effectively over nickel, brass, copper, and zinc alloy substrates.

Ingredients | Scope | Unit |

FH230 Salt for new aquarium | 80-120 | g/L |

FH230 Complexing agent | 40-60 | ml/L |

Temperature | 40-50 | °C |

Proportion | 8-12 | Bome |

Cathode current density | 0.3-1 | A/dm2 |

Anode | Graphite plate or nickel plate |

Premium Finish – Provides a rich black nickel appearance with stable color tone.

Operational Flexibility – Compatible with rack, barrel, and automated plating lines.

Cost Efficiency – Extended bath life and easy maintenance reduce operating costs.

Environmentally Safer Formulation – Designed with optimized additives that reduce harmful by-products.

High Reliability – Backed by strict ISO-certified production standards and advanced R&D.

Wide Industry Applications – Suitable for electronics, hardware, optics, decorative plating, and more.

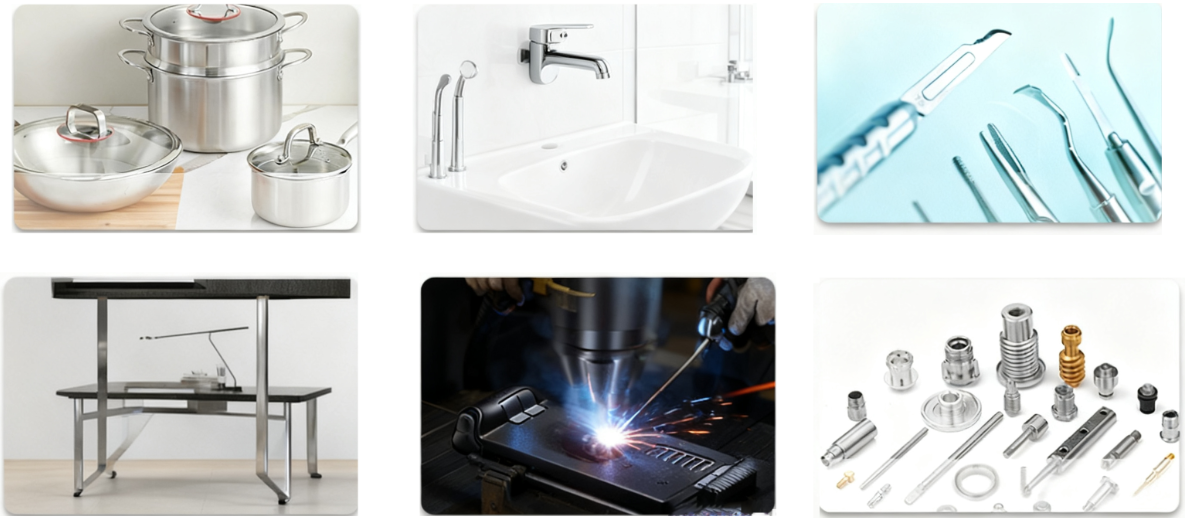

The FH-230 Black Nickel Plating Additive is widely used in:

Electronics Industry: Coating for connectors, electronic housings, and components requiring black finish.

Hardware Manufacturing: Decorative and protective coating for locks, handles, and fasteners.

Optical Instruments: Used in cameras, lenses, and optical housings for reduced reflectivity.

Automotive Industry: Applied on trims, badges, and functional components with high wear resistance.

Luxury Goods & Jewelry: Enhances the appearance of watches, accessories, and decorative products.

Aerospace & Defense: Provides non-reflective surfaces for precision instruments.

Q1: What is black nickel plating used for?

A1: Black nickel plating is used for both decorative purposes (luxury goods, hardware, automotive trims) and functional purposes (optical instruments, aerospace parts) due to its non-reflective and corrosion-resistant properties.

Q2: Can FH-230 be applied over any metal surface?

A2: FH-230 works best on substrates like copper, brass, nickel, and zinc alloys. It is usually plated over a nickel undercoat for enhanced adhesion and performance.

Q3: How stable is the plating bath with FH-230?

A3: FH-230 offers excellent bath stability, maintaining consistent plating quality and uniform coating thickness during extended production.

Q4: Does the black nickel coating provide corrosion resistance?

A4: Yes, FH-230 black nickel coatings offer additional protection against corrosion, especially when applied over nickel underlayers.

Q5: Is the coating reflective?

A5: No, the black nickel finish produced by FH-230 is matte to semi-gloss, with reduced reflectivity, making it ideal for optics and aerospace applications.

Q6: Can FH-230 be used in both manual and automatic plating lines?

A6: Yes, FH-230 is suitable for manual, semi-automatic, and fully automated production lines.

Q7: What industries benefit most from FH-230?

A7: Electronics, automotive, aerospace, hardware, optics, and luxury decorative goods industries are the main beneficiaries of FH-230 black nickel plating.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.