The demand for gun color finishes has increased significantly across industries such as fashion accessories, precision hardware, automotive parts, and electronics. The FH-218 Tin-Nickel Gun Color additive provides an environmentally optimized and efficient plating process that results in durable, scratch-resistant, and corrosion-resistant coatings.

By integrating international advanced additive technology and following ISO9001:2004 quality management standards, FH-218 offers high throwing power, strong adhesion, and smooth alloy distribution. It can be applied in both manual and automated plating systems, ensuring consistent production quality.

Distinctive gun color finish – Produces a deep metallic gray-black color that is elegant and stable.

Alloy stability – Maintains a consistent tin-nickel ratio throughout the plating process.

High Corrosion Resistance – Protects plated parts from rust and oxidation.

Excellent adhesion – Prevents peeling or blistering on the substrate.

Scratch resistance – Provides a durable surface ideal for high-contact components.

Versatile application – Compatible with rack plating, barrel plating, and continuous plating lines.

Environmentally optimized formulation – Reduced toxicity compared to traditional gun-color plating processes.

Ingredients | Scope | Unit |

FH218 Bottle Opener | 1000 | g/L |

pH value | 8.5-9.5 | |

Temperature | 40-50 | °C |

Proportion | 25-30 | Bome |

Cathode current density | 0.5-2 | A/dm2 |

Anode | Graphite plate |

Decorative Finishing – Provides a gun-metallic appearance suitable for hardware, watches, and fashion accessories.

Protective Coating – Acts as a corrosion-resistant and wear-resistant layer.

Functional Alloy Layer – Tin-nickel alloy enhances hardness and improves surface durability.

Surface Refinement – Ensures uniform and smooth plating for high-precision components.

Replacement for Hazardous Processes – Offers a safer alternative to traditional black chromium plating.

Aesthetic Excellence – Creates an attractive and consistent gun-black metallic finish.

Superior Durability – Enhances resistance against scratches, corrosion, and wear.

Cost Efficiency – Long bath life reduces chemical consumption and operating costs.

Stable Performance – Maintains consistent alloy composition for reliable production.

Global Compatibility – Meets international plating standards for decorative and protective applications.

Eco-Friendly Solution – Safer for operators and the environment compared to traditional black plating chemicals.

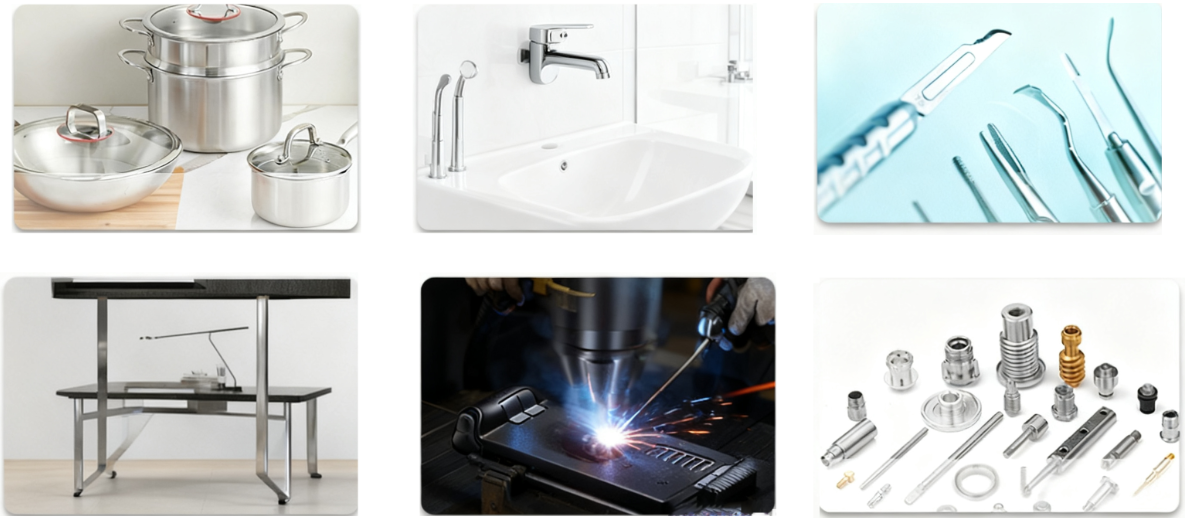

The FH-218 Tin-Nickel Gun Color additive is suitable for a wide range of industries, including:

Fashion Accessories – Watches, jewelry, buckles, and eyewear frames.

Hardware Industry – Tools, fasteners, zippers, and decorative hardware.

Electronics – Connectors, housings, and decorative electronic components.

Automotive Parts – Interior trim, handles, and precision decorative components.

Aerospace & Military – Components requiring durable alloy plating with gun-color appearance.

General Industrial Coating – Any application requiring corrosion-resistant and decorative gun-metal finishes.

Q1: What type of finish does FH-218 produce?

A1: FH-218 produces a deep gun-metallic gray to black finish with a uniform matte shine.

Q2: Is FH-218 suitable for high-volume production?

A2: Yes, FH-218 is stable and effective for both batch plating and automated continuous production lines.

Q3: How does FH-218 compare to black chromium plating?

A3: FH-218 offers similar decorative gun-color results but with reduced toxicity, better adhesion, and higher corrosion resistance.

Q4: What industries benefit most from FH-218 plating?

A4: Electronics, hardware, jewelry, automotive, and aerospace industries widely use FH-218 for both decorative and protective purposes.

Q5: Does FH-218 require frequent bath adjustments?

A5: No, FH-218 has a long bath life with stable performance, requiring only standard maintenance and monitoring.

Q6: Can FH-218 be used on all substrates?

A6: FH-218 works well on ferrous and non-ferrous substrates, ensuring high adhesion and plating consistency.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.