Pearl nickel plating is widely used in the electroplating industry due to its satin-like appearance, strong wear resistance, and corrosion protection. Unlike conventional nickel plating, pearl nickel provides a soft, matte, and elegant finish with improved anti-fingerprint performance, making it ideal for decorative and functional applications.

The FH-2F short-acting pearl nickel additive is formulated with advanced electroplating technology, ensuring short reaction time, easy operation, and high production efficiency. It is suitable for both rack plating and barrel plating, meeting the needs of high-volume production lines.

Developed under strict ISO9001:2004 quality management standards, FH-2F guarantees reliable performance, excellent bath stability, and consistent plating quality across different industries.

Short-acting formula – Delivers faster plating cycles, reducing production time.

Pearl-like finish – Creates a unique satin nickel surface with soft metallic luster.

Excellent throwing power – Ensures uniform plating on complex or irregular parts.

Stable bath performance – Long-lasting chemical stability with minimal maintenance.

Anti-fingerprint property – Provides a clean and durable finish, ideal for decorative uses.

Good adhesion – Strong bonding to base metals, preventing peeling or flaking.

Versatile application – Compatible with rack plating, barrel plating, and automated systems.

Decorative coating – Produces a stylish pearl nickel finish for consumer products.

Protective layer – Enhances corrosion and wear resistance of base metals.

Surface preparation – Serves as an underlayer for chrome plating and other decorative finishes.

Functional coating – Reduces glare and reflection, suitable for automotive interiors and electronic housings.

Durable performance – Ensures long-lasting surface integrity under various conditions.

Ingredients | Scope | Unit |

Nickel sulfate | 420-480 | g/L |

Nickel chloride | 30-40 | g/L |

Borax | 35-45 | ml/L |

FH2F-A Positioning Agent | 10-20 | ml/L |

FH2F-B Auxiliary Agent | 4-12 | ml/L |

FH2F-C Main Sand Agent | 0.5-1 | ml/L |

Proportion | 30-35 | Bome |

Temperature | 50-60 | °C |

pH value | 4.0-4.8 | |

Cathode current density | 4-8 | A/dm2 |

Stir | Swaying or spinning | |

Filtering | Air pump circulation |

High Efficiency – Short plating cycles increase production throughput.

Superior Aesthetics – Unique pearl finish enhances the visual appeal of products.

Cost-effective – Extended bath life and reduced maintenance lower production costs.

Consistent Quality – ISO-certified formulation ensures reliable plating results.

Flexible Applications – Widely used across decorative, industrial, and automotive sectors.

Eco-optimized formulation – Designed with safer ingredients, reducing environmental impact.

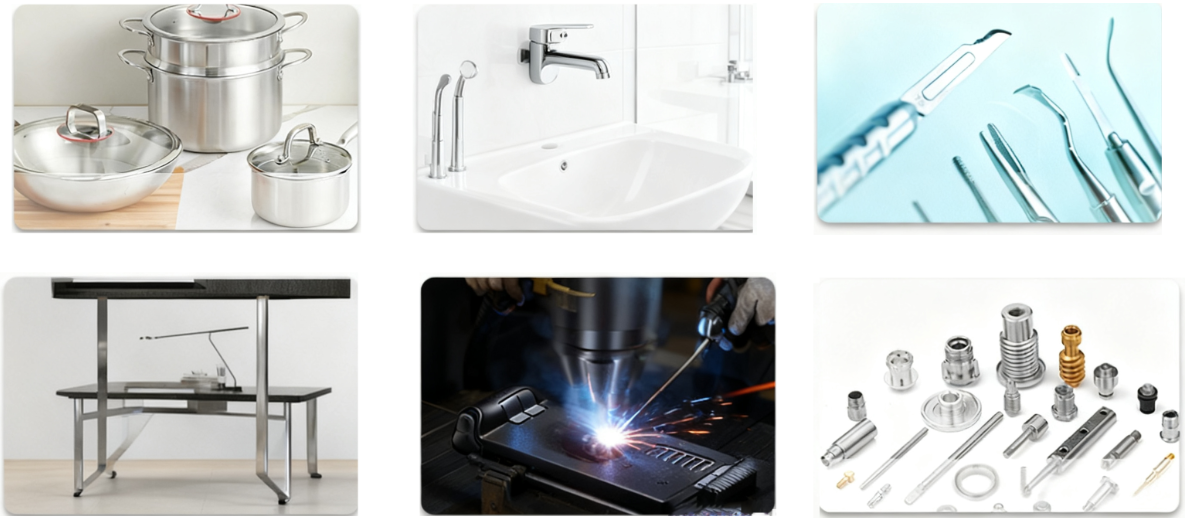

The FH-2F Short-Acting Pearl Nickel additive is suitable for a wide range of industries, including:

Hardware & Tools – Decorative pearl nickel plating for locks, handles, and household hardware.

Automotive Industry – Interior and exterior decorative parts requiring anti-glare coatings.

Consumer Electronics – Matte nickel finish for casings, connectors, and device components.

Jewelry & Accessories – Unique satin metallic look for decorative items.

Home Appliances – Stylish finish for kitchenware, bathroom fittings, and small appliances.

General Industrial Use – Surface treatment for mechanical and precision components.

Q1: What kind of finish does FH-2F produce?

A1: FH-2F produces a satin-like pearl nickel coating with a soft metallic luster and anti-fingerprint property.

Q2: Is FH-2F suitable for both rack plating and barrel plating?

A2: Yes, FH-2F is highly versatile and suitable for different plating methods, including automatic production lines.

Q3: How does FH-2F compare to conventional nickel plating?

A3: Unlike standard nickel plating, FH-2F creates a matte, pearl-like decorative surface with enhanced aesthetics and better glare reduction.

Q4: Does FH-2F require frequent bath maintenance?

A4: No, FH-2F offers stable chemical performance and long bath life, requiring minimal maintenance.

Q5: What industries commonly use FH-2F pearl nickel?

A5: It is widely applied in hardware, automotive, electronics, decorative plating, jewelry, and home appliances.

Q6: Can FH-2F pearl nickel be used under chromium plating?

A6: Yes, FH-2F is often used as an underlayer before decorative chromium plating for improved appearance and protection.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.