1. Environmentally Friendly product, free of hexavalent chromium, simple wastewater treatment.

2. It has uniform and beautiful color, and excellent covering and even plating capabilities.

3. The plating solution contains no organic solvents and has good tolerance for sulfate ions and chloride ions.

4. Power-off during electroplating will not cause adverse consequences, and the deposition speed is faster than that of hexavalent chromium.

5. The adoption of graphite anodes provided by German KOZO can enhance quality and increase the stability of the plating solution.

trivalent chromium plating, also known as Cr³⁺ plating, has become the global standard for environmentally compliant electroplating applications. With the tightening of international environmental policies, industries are rapidly transitioning from hexavalent chromium (Cr⁶⁺) processes to safer alternatives.

Our trivalent chromium plating technology is formulated with innovative Electroplating Additives that deliver bright, uniform, and durable finishes suitable for both decorative and functional applications. Backed by ISO9001:2004 quality management and advanced R&D capabilities, this process ensures superior plating performance while maintaining compliance with global RoHS, REACH, and ELV regulations.

Eco-friendly formulation – Free from hazardous hexavalent chromium compounds.

Regulatory compliance – Meets international environmental standards such as RoHS, REACH, and ELV.

High Corrosion Resistance – Provides long-lasting protection against rust and wear.

Bright and uniform finish – Delivers decorative quality comparable to traditional Cr⁶⁺ plating.

Stable plating bath – Excellent solution stability with low maintenance requirements.

Flexible application – Suitable for rack plating, barrel plating, and high-speed automatic plating lines.

Cost-efficient – Optimized additive consumption reduces overall production costs.

Ingredients | Scope | Unit |

FH592 Conducting Salt | 280-320 | g/L |

FH592 Chromium salts | 120-180 | g/L |

FH592 Stabilizer | 50-80 | ml/L |

FH592 Moisturizer | 2-4 | ml/L |

FH592 Crosslinker | 2-4 | ml/L |

pH value | 2.5-3 | |

Temperature | 30-40 | °C |

Plating solution specific gravity | 25-28 | |

Cathode current density | 10-20 | A/dm2 |

Anode current density | 3.5-5 | A/dm2 |

Decorative plating – Produces a bright, mirror-like surface finish for aesthetic appeal.

Protective coating – Enhances corrosion resistance and wear resistance of metal components.

Functional Surface treatment – Improves hardness, durability, and chemical resistance.

Eco-compliant replacement – Serves as a direct substitute for hazardous hexavalent chromium plating.

Environmental Responsibility: Safe for operators and significantly reduces environmental pollution.

Enhanced Durability: Provides strong adhesion and excellent wear resistance on different substrates.

Global Market Acceptance: Adopted widely in automotive, electronics, aerospace, and consumer goods industries.

High Efficiency: Faster plating speed and stable bath chemistry ensure consistent results.

Sustainable Production: Supports green manufacturing initiatives and reduces waste treatment costs.

Wide Applicability: Compatible with steel, aluminum, copper, zinc alloys, and other base materials.

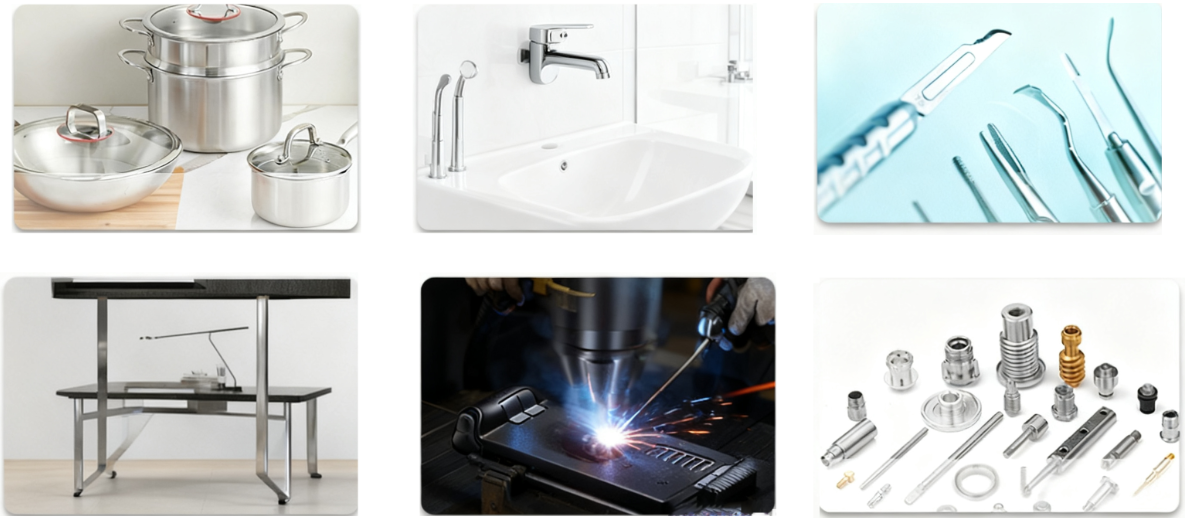

The Environmentally Friendly Trivalent chromium plating process is suitable for:

Automotive industry: Decorative and protective plating on trims, wheels, and interior/exterior components.

Electronics: Surface finishing of connectors, housings, and precision parts.

Hardware manufacturing: Handles, tools, fasteners, and household products.

Aerospace: High-performance protective coatings for aircraft components.

Medical devices: Safe and durable plating for surgical instruments and stainless-steel devices.

Consumer goods: Watches, eyewear frames, bathroom accessories, and decorative items.

Q1: What is the difference between trivalent chromium plating and hexavalent chromium plating?

A1: Trivalent chromium plating (Cr³⁺) is environmentally friendly, non-toxic, and compliant with global regulations, while hexavalent chromium plating (Cr⁶⁺) is hazardous and increasingly restricted worldwide.

Q2: Does trivalent chromium plating provide the same brightness as hexavalent plating?

A2: Yes, our advanced additives ensure that trivalent chromium finishes achieve a bright, mirror-like appearance comparable to traditional hexavalent coatings.

Q3: Is the corrosion resistance of trivalent chromium plating sufficient for industrial use?

A3: Absolutely. The process delivers excellent corrosion and wear resistance, making it suitable for automotive, aerospace, and high-performance applications.

Q4: Can this plating process be used in existing plating lines?

A4: Yes, it is compatible with most existing plating equipment with minimal adjustments, making it easy to adopt.

Q5: Is trivalent chromium plating more expensive than traditional methods?

A5: While the initial setup may require adjustments, the long bath life, reduced waste treatment costs, and compliance benefits make it more cost-effective in the long term.

Q6: What substrates are suitable for trivalent chromium plating?

A6: It can be applied to a wide range of substrates including steel, aluminum, zinc alloys, and copper alloys.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.