1. Environmentally Friendly product, free of hexavalent chromium, simple wastewater treatment.

2. The coating is carbon black, crystal clear and beautiful, with excellent coverage and even plating capabilities.

3. The plating solution contains no organic solvents and has good tolerance for sulfate ions and chloride ions.

4. Power-off during electroplating will not cause adverse consequences, and the deposition speed is faster than that of hexavalent chromium.

5. The adoption of graphite anodes provided by German KOZO can enhance quality and increase the stability of the plating solution.

Ingredients | Scope | Unit |

FH596 Salt for aquarium opening | 280-320 | g/L |

FH596 Chromium Salt | 120-160 | g/L |

FH596 Stabilizer | 50-80 | ml/L |

FH596 Surfactant | 2-4 | ml/L |

FH596 Complexing agent | 30-50 | ml/L |

FH596 Additive | 15-25 | ml/L |

pH value | 2.5-2.8 | |

Temperature | 28-40 | °C |

Plating solution specific gravity | 25-28 | |

Cathode current density | 10-30 | A/dm2 |

Anode current density | 3.5-5 | A/dm2 |

Traditional hexavalent chromium plating has long been associated with excellent hardness and Corrosion Resistance but raises serious environmental and health concerns. The FH-596 Trivalent chromium plating process is formulated with advanced Electroplating Additives that eliminate hexavalent chromium, delivering a green plating solution that complies with global environmental regulations.

FH-596 is engineered to provide consistent black chromium finishes with excellent adhesion, wear resistance, and durability. The process ensures uniform coatings with excellent decorative appeal, making it suitable for both functional and aesthetic applications. Supported by Shenzhen Xinfuhua’s cutting-edge R&D capabilities and strict ISO9001:2004 quality management standards, this process guarantees stable production performance and outstanding surface quality.

Eco-Friendly & Non-toxic: Replaces hazardous hexavalent chromium with safe trivalent chromium.

Black Chromium Finish: Produces deep, uniform black coatings with high decorative appeal.

Superior Corrosion Resistance: Excellent protection against rust and environmental exposure.

High Hardness & Wear Resistance: Extends product life cycle in demanding conditions.

Uniform Deposition: Ensures consistent coverage even on complex geometries.

Compliance with Regulations: Fully meets RoHS, REACH, and other international environmental standards.

Cost Efficiency: Lower waste treatment and reduced Environmental Compliance costs.

Surface Protection: Prevents oxidation and enhances corrosion resistance.

Aesthetic Enhancement: Provides a sleek, modern, and durable black finish.

Functional Performance: Improves hardness, scratch resistance, and wear resistance.

Eco-Safe Substitution: Serves as a direct replacement for toxic hexavalent chromium processes.

Industrial Compatibility: Suitable for rack, barrel, and automated plating lines.

Environmental Responsibility – Safe, eco-friendly formulation with minimal hazardous waste.

Regulatory Compliance – Fully aligned with global green manufacturing standards.

Stable Process Control – Ensures consistent plating quality across large-scale production.

Enhanced Market Competitiveness – Meets international demand for sustainable coatings.

Cost Reduction – Lower wastewater treatment and environmental monitoring expenses.

Wide Industry Application – Trusted by automotive, aerospace, electronics, and hardware industries.

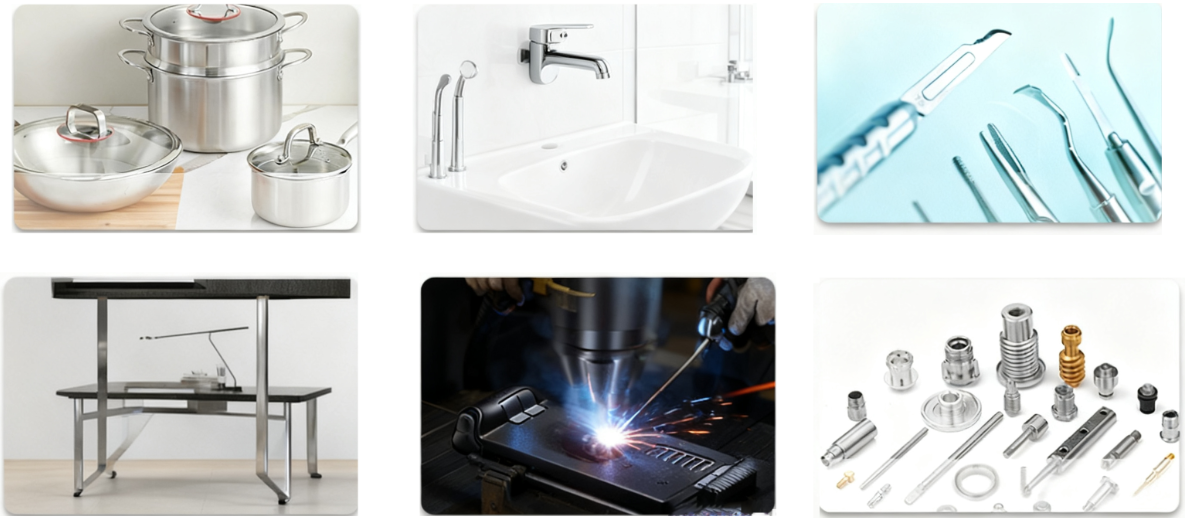

The FH-596 Eco-Friendly Trivalent chromium plating process is widely applied in:

Automotive Industry: Black chromium plating for trim, handles, exhaust parts, and decorative elements.

Electronics & Consumer Goods: Durable, corrosion-resistant coatings for mobile devices, watches, and home appliances.

Aerospace & Defense: Functional black chromium finishes on precision aircraft and military components.

Hardware & Tools: Strong and attractive coatings on tools, fasteners, and metal accessories.

Medical Equipment: Safe, non-toxic plating suitable for stainless steel medical instruments.

Decorative Applications: Fashion accessories, jewelry, and decorative metal products requiring a modern black finish.

Q1: What is the difference between trivalent and hexavalent chromium plating?

A1: Trivalent chromium is a safer, environmentally friendly alternative to hexavalent chromium. It provides similar or better performance without toxic environmental and health risks.

Q2: Can FH-596 be used as a direct replacement for hexavalent chromium plating?

A2: Yes, FH-596 is specifically designed as a substitute for traditional hexavalent chromium, offering comparable hardness, durability, and appearance.

Q3: Does FH-596 comply with international environmental standards?

A3: Absolutely. FH-596 meets RoHS, REACH, and other global eco-regulatory requirements, ensuring safe use in worldwide markets.

Q4: What industries benefit most from FH-596?

A4: Automotive, aerospace, electronics, hardware, decorative finishing, and medical equipment industries benefit from its corrosion resistance and eco-safe plating properties.

Q5: What color finish does FH-596 produce?

A5: FH-596 produces a deep, uniform black chromium finish, highly suitable for both decorative and functional applications.

Q6: Is FH-596 plating cost-effective?

A6: Yes, thanks to its reduced environmental treatment costs, stable long-term performance, and compliance with green regulations, FH-596 lowers overall production costs.

The FH-596 Eco-Friendly Trivalent Chromium Plating Process by Shenzhen Xinfuhua Surface Technology Co., Ltd. represents the future of sustainable electroplating. With its environmental compliance, superior coating properties, and stable production performance, FH-596 is the ideal choice for industries seeking to balance performance with environmental responsibility.

By adopting this trivalent chromium process, manufacturers can not only achieve high-quality black chromium finishes but also align with global sustainability goals and regulatory requirements, ensuring long-term competitiveness in international markets.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.