1. Quick light emission, high filling, high migration.

2. Wide current density can also achieve mirror effect, the low current density area is filled well, and the coating is bright.

3. Particularly high tolerance for impurities, not prone to pitted, pinhole, white mist.

4. Simple operation, easy maintenance, low consumption of brightener, low cost.

Ingredients | Scope | Unit |

Copper sulfate | 160-220 | g/L |

Sulfuric acid | 35-45 | g/L |

Chloride ion | 0.15-0.25 | g/L |

FH910M Bottle Opener | 4-6 | ml/L |

FH910A Brightener | 0.2-0.4 | ml/L |

FH910B Filler | 0.1-0.3 | ml/L |

Temperature | 15-25 | °C |

Anode current density | 1.5-8 | A/dm2 |

Anode | Phosphor brass | |

Stir | Continuous filtration and air stirring |

The FH-910 Acid bright copper plating Process is a high-quality electroplating additive developed by Shenzhen Xinfuhua Surface Technology Co., Ltd., a leading enterprise specializing in the R&D, production, and sales of Electroplating Additives since 2005. As a professional manufacturer dedicated to providing electroplating technical services, we have introduced the FH-910 bright acid copper plating solution to meet the increasing demand for superior copper plating in industries such as electronics, automotive, telecommunications, and decorative hardware.

This process delivers high leveling ability, excellent brightness, strong adhesion, and ductility, making it ideal for both functional and decorative copper plating applications. Supported by advanced analytical technology and ISO9001:2004 international quality standards, the FH-910 system provides consistent and reliable results across large-scale production lines.

Bright acid copper plating plays a crucial role in the electroplating industry, not only as a decorative finish but also as a functional underlayer for nickel, chromium, or other coatings. The FH-910 Acid bright copper plating Process is formulated with advanced brighteners and additives to ensure superior leveling power, uniform coating thickness, and excellent throwing power even on complex-shaped components.

Developed through years of research and continuous improvement, FH-910 is designed to meet the needs of modern industries requiring high-quality plating with stable bath performance. It is widely used in both rack plating and barrel plating, making it suitable for various component sizes ranging from precision electronic connectors to large hardware parts.

The formulation incorporates state-of-the-art organic brighteners and auxiliary additives that work synergistically to produce mirror-like copper deposits. It not only enhances surface appearance but also improves coating conductivity, solderability, and Corrosion Resistance.

High Brightness and Gloss – Produces uniform, mirror-like bright copper deposits.

Excellent Leveling Power – Smooths surface irregularities and ensures even thickness.

Superior Throwing Power – Achieves consistent plating results on complex geometries and recessed areas.

Strong Adhesion – Ensures firm bonding between the copper layer and the substrate.

Ductility and Flexibility – Provides a durable coating resistant to cracking during forming.

Stable Bath Performance – Maintains consistent quality even under continuous production conditions.

Easy Maintenance – Simple bath control with convenient replenishment procedures.

Wide Compatibility – Applicable in both rack and barrel plating operations.

Decorative Enhancement: Creates an attractive copper finish with brilliant luster for decorative hardware, household items, and luxury goods.

Functional Undercoat: Serves as an intermediate layer before nickel, chromium, or precious metal plating, improving adhesion and durability.

Electrical Conductivity: Enhances conductivity of electronic components and connectors.

Corrosion Resistance: Provides a protective barrier against oxidation and environmental degradation.

Leveling and Smoothing: Eliminates minor surface defects, scratches, and machining marks for a flawless final appearance.

Improved Solderability: Ensures reliable soldering for electronic assemblies and printed circuit boards.

Consistent High-Quality Results: Guaranteed by ISO-certified quality control processes.

Increased Productivity: Fast deposition rates improve efficiency in industrial-scale production.

Cost-Effective Operation: Long bath life reduces chemical consumption and operational costs.

Environmentally Responsible: Designed with reduced harmful emissions compared to traditional systems.

Versatile Applications: Suitable for multiple industries including electronics, automotive, aerospace, telecommunications, and decorative hardware.

Reliable Technical Support: Backed by Shenzhen Xinfuhua’s professional R&D and technical service team.

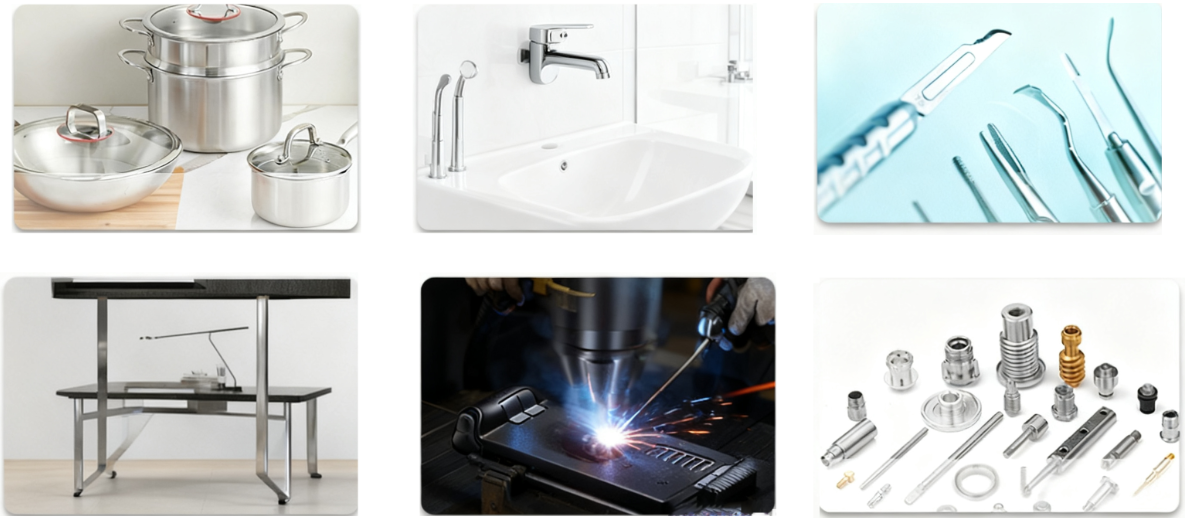

The FH-910 Acid Bright Copper Plating Process is widely applied in industries requiring high-performance copper coatings:

Electronics & PCB Manufacturing: For connectors, circuit boards, and micro-components requiring conductivity and solderability.

Automotive Industry: Used for functional and decorative plating of auto parts such as handles, trims, and connectors.

Telecommunications: Applied to electronic components, connectors, and communication devices requiring reliable conductivity.

Aerospace & Aviation: Ensures durable and high-quality copper coatings for precision parts.

Hardware & Decorative Items: Produces attractive finishes for tools, fasteners, jewelry, and consumer goods.

Medical Devices: Provides high-purity, corrosion-resistant coatings for surgical instruments and equipment.

Q1: What is the main benefit of FH-910 compared to standard acid copper plating?

A1: FH-910 provides superior brightness, leveling, and ductility, making it suitable for both decorative and functional plating applications.

Q2: Can FH-910 be used as a base layer before nickel and chromium plating?

A2: Yes, FH-910 is an excellent undercoat that improves adhesion, enhances corrosion resistance, and ensures a smooth surface for subsequent plating.

Q3: What plating methods are compatible with FH-910?

A3: FH-910 can be used in both rack plating and barrel plating operations, covering a wide range of part sizes.

Q4: How easy is it to maintain the FH-910 bath?

A4: The process requires only simple bath monitoring and periodic replenishment of additives, making it easy to maintain stable performance.

Q5: Does FH-910 meet environmental and safety standards?

A5: Yes, FH-910 is formulated with environmentally responsible chemistry and complies with international safety standards.

Q6: What industries benefit most from FH-910 bright copper plating?

A6: Electronics, automotive, telecommunications, aerospace, decorative hardware, and medical device industries all benefit from its performance.

Q7: How does FH-910 improve final product quality?

A7: By providing mirror-like brightness, excellent leveling, and strong adhesion, FH-910 enhances both the functional and aesthetic quality of plated components.

Email:fuhuaguoji@yeah.net

Address: Room 2101, Building 1, Hegushan Huicheng, No. 35, Guangtian Road, Bao 'an District, Shenzhen City, Guangdong Province (Office Space)

Copyright © 2025 Shenzhen Xinfuhua Surface Technology Co., Ltd. All rights reserved seo:hzw

SitemapThis website uses cookies to ensure you get the best experience on our website.